What not to do when using Stainless Steel Fasteners!

10M from the sea. Bracket is 304 and showing signs of rust. 316 nuts/bolts are performing well.

The DOs and DON'Ts of using Stainless Steel Fasteners

To help you avoid the common mistakes made when specifying and using stainless fasteners, we have put together a short DOs and DON'Ts guide.

1. DO: Select the Right Grade

There are many different grades of stainless steel. The two commonly used grades are 304 and 316, with 316 being more corrosion resistant than 304. The rule-of-thumb is that if the fastener is in a corrosive environment (e.g. within 5km of the coast), 316 is preferable, particularly if the fastener is to be seen, as 316 is less likely to 'tea-stain' or develop a brown discolouration (see photo of bracket showing tea-staining).

In addition to 304 or 316, there are other grades specifically suited to different applications. Please see our guide to selecting the correct grade of stainless steel for your fastener.

2. DO: Lubricate Threads

Top stainless fastener engineers recommend all stainless steel threads should be lubricated before being assembled, to reduce the risk of galling (this is when threads lock up). We have found the most risk of galling is with larger threads (M16 upwards), and also when using Nyloc nuts. We suggest 'Lanotec' or 'Nickel Anti-Seize' lubricants such as Loctite 771 (Anzor stocks).

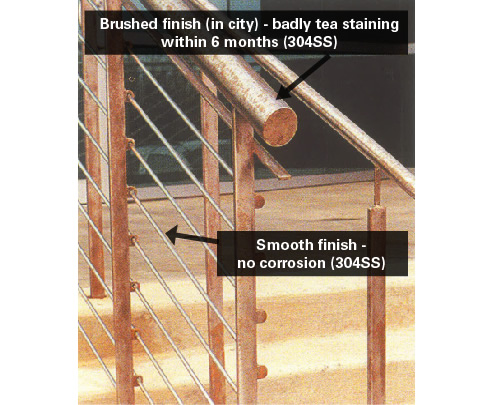

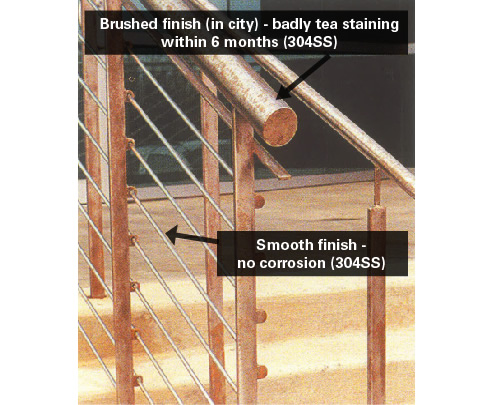

3. DO: Select the Right Surface Finish

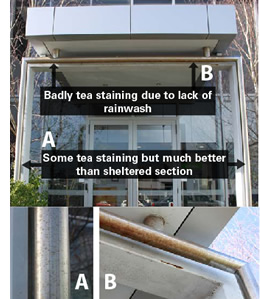

The smoother or more polished the finish, the better the corrosion resistance. Some stainless products have a brushed, satin or 'rougher' finish - e.g. sometimes on hinges, fittings, downpipes. This type of finish can trap minute particles (e.g. salt) which damage the protective chromium oxide layer on the stainless steel, causing 'tea-staining', and therefore giving a rusty appearance. This is made worse if the stainless steel is not exposed to rainwater to wash off the particles (see #5 and #6 below).

Select the Right Surface Finish

4. DO: Consider Electropolishing

Electro-polishing or passivating (forms of acid treatment) improve corrosion resistance by thickening the naturally occurring protective chromium oxide layer that forms on stainless steel. All stainless steel fasteners supplied by Anzor are passivated and can also be Electro-polished upon request. Anzor stocks 316 Butt Hinges already Electro-polished.

5. DO: Establish and Follow a Cleaning Schedule

Stainless Steel products 'on show' need be cleaned to remove contaminants (e.g. salt) and therefore maintain the stainless steel's appearance. For more information, please see see our Cleaning Guidelines.

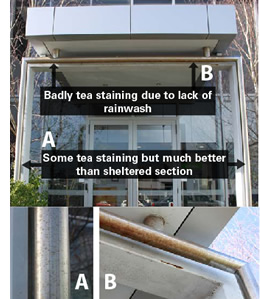

6. DO: Consider Exposure to Rainwater

Stainless steel resists corrosion due to it's naturally occurring protective layer ('Chromium Oxide'). When contaminants settle on stainless steel, depending on the grade and the surface finish, these can damage this protective layer, allowing oxygen to react with the iron in the stainless steel causing it to rust. If the stainless steel is exposed to rainwater, then this should wash these contaminants away, restoring the stainless steel's protective layer.Therefore if stainless steel is going to be sheltered from the rain, and it is in a corrosive environement, then consider options to enhance the corrosion resistance: select a more corrosion resistant grade; a smooth/polished/mirror finish; and electro-polishing.

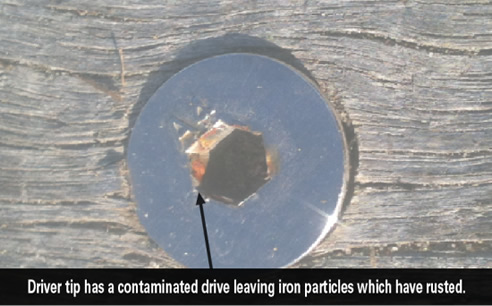

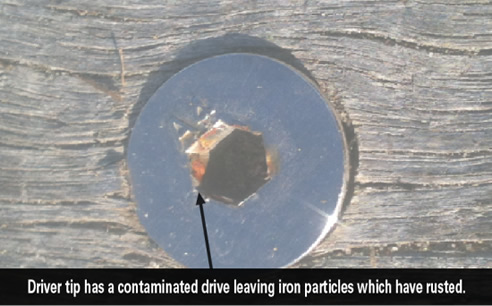

7. DON'T: Contaminate

This is where your tools pass on minute contaminants (e.g. iron filings). These rust on the surface of the stainless steel and kick-start corrosion. This can also occur when iron fillings, say from grinding steel, are blown onto stainless steel.

DON'T: Contaminate

How do you reduce the risk of contamination?

- Drive/Screw Tips should be Chrome Vanadium steel (Anzor stocks)

- Allen Keys should be Hardened-Chrome plated (Anzor stocks)

- Cutting Wheels should be made from Aluminium Oxide, be 'iron' or 'carbon - steel' free, or be labelled "For Stainless Steel".

- Hammers should be good quality hardened-chrome plated steel or stainless steel.

- Cover stainless steel with plastic wrap or something else suitable to protect it from iron filings, until work on a job site is complete.

- NB: all these tools should be kept just for stainless steel.

8. DON'T: Cause Galvanic Corrosion

This is where two dissimilar metals are in contact, react and cause corrosion. For example, lead or copper flashings on a zinc/aluminium roof. Galvanic corrosion may be a risk for the other metals when they are in contact with stainless steel and the join is wet. We recommend investigating situations where you have concerns related to possible Galvanic corrosion. Isolating metals with Tef-Gel or nylon/rubber barriers (e.g. a nylon washer) is a way to keep the metals apart to reduce the risk of this occuring. Note however, it still may occur one metal might be contaminated by another after water passes from one to the other.

9. DON'T: Unwittingly Buy Low Nickel Stainless Steel

We are aware of low-nickel, high-maganese (200 series) stainless fasteners on the market. They usually have lower chromium and are more susceptible to rusting.

Anzor only deals with high quality, reputable suppliers. We also have a material testing programme using an X-Ray Spectrometer to provide quality assurance.

NB: This information is provided as a guide only and Anzor does not accept liability for the application of this information. Specific technical advice for critical applications should be sought from the Australian Stainless Steel Development Association.

|

Corrosion Resistant Fasteners - Super

Corrosion Resistant Fasteners - Super Stainless Steel Hex Bolts and Setscrews

Stainless Steel Hex Bolts and Setscrews Pipe and Tube Fittings | Anzor

Pipe and Tube Fittings | Anzor Stainless Steel Fittings | Anzor

Stainless Steel Fittings | Anzor Anzor Barrel Nuts Supports 'Creative

Anzor Barrel Nuts Supports 'Creative Avoid Galling with Anti-Seize Lubricants

Avoid Galling with Anti-Seize Lubricants Stainless Steel Security Screws | Anzor

Stainless Steel Security Screws | Anzor Stainless Steel Wire Balustrades and

Stainless Steel Wire Balustrades and Need a Stainless Tee Nut in your Timber?

Need a Stainless Tee Nut in your Timber? Stainless Steel Fasteners with Treated

Stainless Steel Fasteners with Treated Stainless Steel Self Drilling Tek Screws

Stainless Steel Self Drilling Tek Screws Stainless Steel Wire Balustrading Deal

Stainless Steel Wire Balustrading Deal Stainless Steel Fasteners and Fittings

Stainless Steel Fasteners and Fittings Stainless Steel Barrel Nuts | Anzor

Stainless Steel Barrel Nuts | Anzor Anzor Fasteners - What makes Stainless

Anzor Fasteners - What makes Stainless