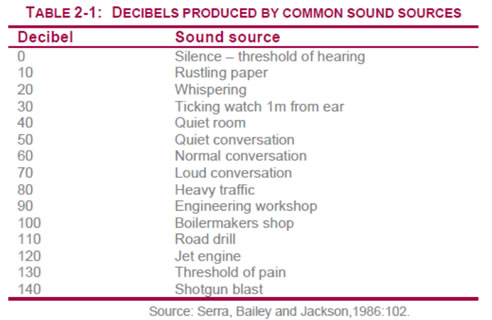

Machinery Noise Solutions from Pyrotek Noise Control Lights Out - Pyrotek turns off loud noise during manufacturing Lightforce, based in Adelaide; South Australia, has built a formidable reputation as a global leader in innovative design and excellence in the manufacture of high-performance and durable lighting systems for professionals and sporting enthusiasts. Based around the framework of ISO 9001:2008 (Australian Quality Standards) Lightforce's manufacturing capability and capacity is agile to enable them to meet the most challenging and ever-changing market demands. Lightforce use state of the art equipment in their manufacturing process. One of these machines, a 2000X Ultrasonic Plastic Welder, used in the manufacturing process for Lightforce's high visibility lights for night driving, hunting and outdoor activities, was emitting 116 dB(A) during the welding process. This unprecedented level of noise was well above the AS/NSZ 1269.1: 2005 noise emission and exposure standard of 85 dB(A) for an 8-hour period. Research conducted by Serra, Bailey and Jackson (1986:102) displayed in Access Economics (2006) hearing loss report, showed this level of noise to be the equivalent of the noise levels of a road drill at 110 dB(A) and a jet engine at 120 dB(A).

Relocating the machine from an open area to a more confined area within the manufacturing plant further exacerbated the noise issue.

According to the World Health Organisation (WHO) (2004:4), some of the consequences of noise induced hearing loss (NIHL) include:

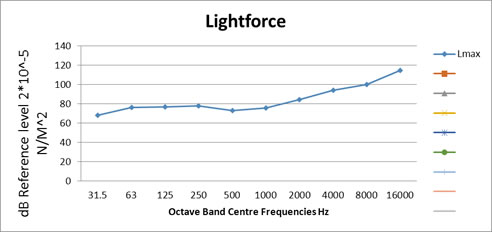

After initial testing was conducted by Pyrotek branch manager, Rob Thomas, it can be clearly seen that the noise problems are in the frequency range 2000 Hertz (Hz) and above as shown in the graph below. If these high noise levels continued, Lightforce employees would be at risk of NIHL and being subject to some or all of the above-mentioned consequences.

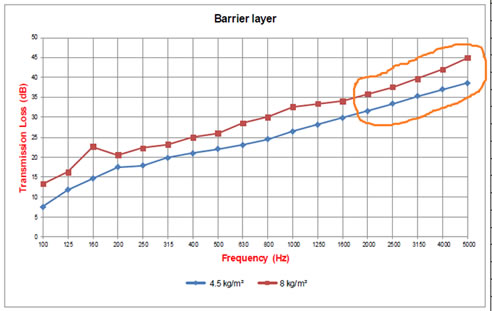

Lightforce wished to customise an aluminium enclosure around the machine. Pyrotek was able to recommend the use of 32mm thick Sorberbarrier 4kg/m2 with an aluminium-facing as a lining for the enclosure.

Sorberbarrier was developed to provide a complete noise control solution within one high performance and versatile product. The unique construction of Sorberbarrier comprises two of Pyrotek's flagship products; Wavebar (a high-mass, flexible noise barrier) laminated between two layers of Sorberfoam (flexible acoustic foam) provides a sound absorption layer and a decoupling layer. Sorberbarrier was chosen due to Pyrotek product test data showing it to be effective at reducing noise levels in the troublesome frequencies as shown in the graph below.

Following the insulation installation, Lightforce was very pleased with the result. Subsequent internal testing by Lightforce showed the Sorberbarrier 32mm 4kg/m2 enclosure had lowered the noise level during machine operation from 116 dB(A) to under 85 dB(A), so it now met standard AS/NZS 1269.1: 2005 for noise emissions and exposure. These lower noise level results eliminated a lot of the risk employees faced in being diagnosed with NIHL.

Reference List

|

(02) 8868 2000 Girraween, NSW, 2145

|

Acoustic Plywood Panels for Yachts by

Acoustic Plywood Panels for Yachts by Noise Absorber for Tunnels by Pyrotek

Noise Absorber for Tunnels by Pyrotek Fyrewrap Marine Blanket by Pyrotek

Fyrewrap Marine Blanket by Pyrotek Litecore Marine Panel by Pyrotek

Litecore Marine Panel by Pyrotek Soundproofing for Pipes and Ducts by

Soundproofing for Pipes and Ducts by Industrial Noise Curtains by Pyrotek

Industrial Noise Curtains by Pyrotek Foil Faced Noise Barrier by Pyrotek

Foil Faced Noise Barrier by Pyrotek Marine Exhaust Systems by Pyrotek

Marine Exhaust Systems by Pyrotek Acoustic Lagging Solution for Cinemas by

Acoustic Lagging Solution for Cinemas by Mineral Wool Marine Insulation by

Mineral Wool Marine Insulation by Acoustic Absorbers for Outdoor

Acoustic Absorbers for Outdoor Vibration Damping Compound by Pyrotek

Vibration Damping Compound by Pyrotek Custom Removable Insulation Covers for

Custom Removable Insulation Covers for Flying Boats in Dubai | Pyrotek

Flying Boats in Dubai | Pyrotek Wavebar Roof in Classrooms by Pyrotek

Wavebar Roof in Classrooms by Pyrotek Removable Insulation Covers by Pyrotek

Removable Insulation Covers by Pyrotek Soundlag Acoustic Insulation for Cinemas

Soundlag Acoustic Insulation for Cinemas Australian-made Mass Loaded Vinyl Noise

Australian-made Mass Loaded Vinyl Noise Elevator Shaft or Chute Noise Control

Elevator Shaft or Chute Noise Control World-class Studio Soundproofing with

World-class Studio Soundproofing with