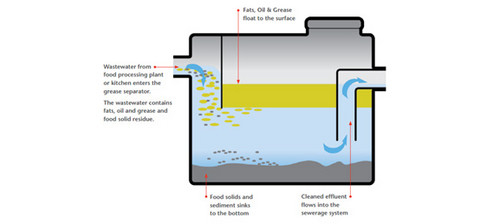

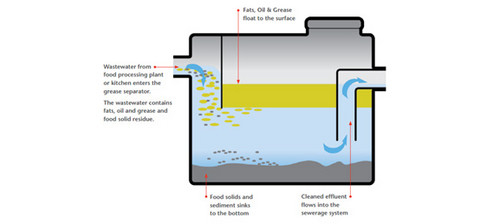

The principle is simple. Light substances (fats and oils) rise to the top of the grease separator and heavy substances (grease and food waste) sink, as treated wastewater continues through to the sewers via a drainage outlet pipe.

This article will show you that not only are ACO's separator systems highly advanced, they're compliant to the requirements of the water industry, councils, building operators and other stakeholders.

The Management of Fats, Oils and Grease

As one of the most detrimental problems found within food processing industry and commercial buildings, the build-up of fats, oils and grease (also known simply as 'FOG') presents a significant challenge. This causes pungent odour and reduces the efficiency of pipes due to solidification. Ultimately, these problems lead to an increase in maintenance which costs you both time and money over the life of a building.

Fortunately, animal and vegetable fats can be separated easily within a gravity grease separator.

The image below demonstrates how wastewater from food processing plants enters the grease separator, and shows you how FOG substances rise and float to the surface:

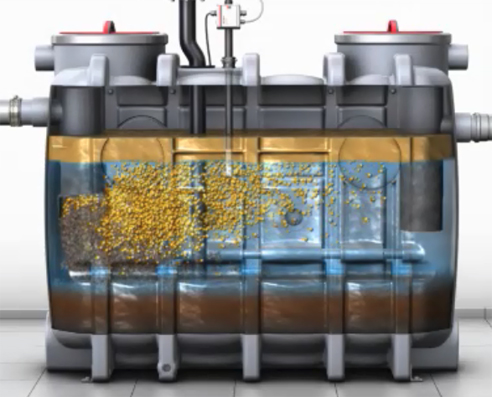

Additionally, grease separators can be used for more substantial installations where necessary, in order to manage larger hydraulic demands. Turbulence can be reduced and hydraulic flow and efficiency can be maintained by incorporating a flow distributor for splitting flow into different separators.

Grease Separator Products

ACO offers two products which are equally as effective at separating FOG substances, but designed specifically for different applications:

EcoJet (for above ground installation)

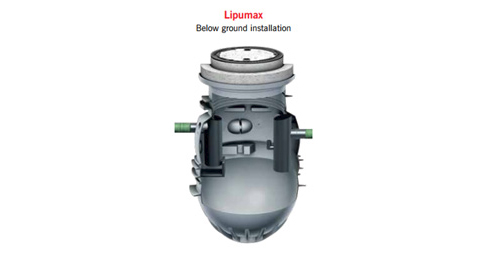

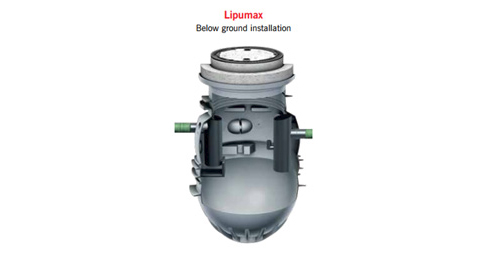

Lipumax (for underground installation)

Material properties of grease separators

Separator bodies can be manufactured from a choice of materials. These can have a significant impact upon the separator's durability, design and lifespan. Whilst not obvious to the purchaser or specifier, some contain implicit weaknesses that can lead to early failure. Let's take a look at some of the most common materials used:

Fibreglass

This is a low cost material which is frequently used for grease separators. Fibreglass is a material that can be difficult to cut; and may cause handling issues due to the fact that the glass fibres are abrasive. Additionally, fibreglass separators are known to require regular maintenance - including relining to prevent groundwater contamination.

Cement Concrete

These bodies require thick walls to provide structural integrity; precast concrete separators involve high installation costs as they are heavy and cumbersome. Cranes and other types of lifting equipment will be required throughout the installation process. Cement concrete is generally prone to deterioration and separators made from this material also require relining.

Glass Reinforced Concrete

Occasionally used in the manufacturing of grease separators, glass reinforced concrete contains a mixture of elements including glass fibres, cement, chemical admixtures, water and fine aggregate. Although GRC is lightweight, it is brittle, prone to cracking and deterioration and as a result of this, does require relining and repair.

Rotomoulded Polyethylene

Polyethylene is the best option for use in the manufacturing of grease separators. Exhibiting excellent long-term corrosion resistance, this material is lightweight and flexible, making it an ideal option for installation, particularly in sensitive environments. Chemically resistant, polyethylene doesn't require lining and therefore is superior when in contact with wastewater and strong cleaning agents

If you want to find out more about ACO's grease separators, get in touch with us by calling on 1300 765 226.

Sloped Trench Drains for Sports

Sloped Trench Drains for Sports Heelsafe Anti-slip Grates and Covers

Heelsafe Anti-slip Grates and Covers Balcony Drains for Sydney Apartments

Balcony Drains for Sydney Apartments Bridge Stormwater Drainage with

Bridge Stormwater Drainage with Custom Sloped Channel Drainage for Pools

Custom Sloped Channel Drainage for Pools Slip-Resistant Push-Fit Drainage for

Slip-Resistant Push-Fit Drainage for Grease Management and Drainage for

Grease Management and Drainage for Freestyle Architectural Drain Grates -

Freestyle Architectural Drain Grates - Surface Water & Cable Management of Rail

Surface Water & Cable Management of Rail KerbDrain Trench Drain System for Camden

KerbDrain Trench Drain System for Camden Trench Drain Shape and Hydraulic

Trench Drain Shape and Hydraulic Multipart Access Cover Installation

Multipart Access Cover Installation Drainage for Road Infrastructure by ACO

Drainage for Road Infrastructure by ACO Steel Production for Construction Across

Steel Production for Construction Across Surface Drainage for Construction by ACO

Surface Drainage for Construction by ACO Non-Slip Drainage for Public Area from

Non-Slip Drainage for Public Area from Hygienic Grease Management for

Hygienic Grease Management for Grease Management and Drainage System

Grease Management and Drainage System Trench Drains for Transport

Trench Drains for Transport New Trench Drain Technical Handbook by

New Trench Drain Technical Handbook by