Multipart Access Cover Installation Guidelines from ACO

Guidelines for Installing Multipart Systems

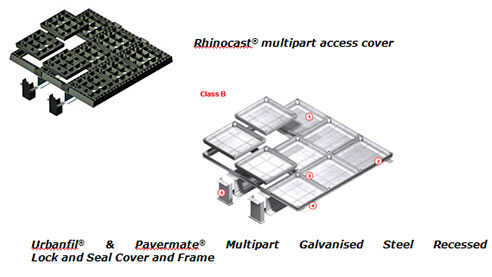

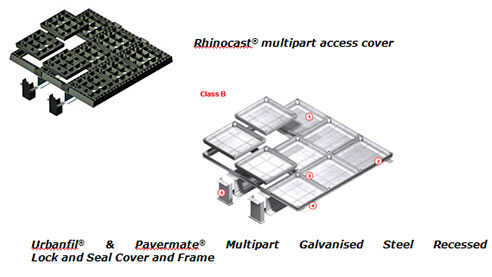

At ACO, we assemble Rhinocast®, Urbanfil® and Pavermate® multipart access cover systems that combine standard size covers in multiple rows and lengths to adapt to many applications. In these systems, provided each row in the system has covers of the same length and load class, the width of the individual covers can vary, allowing for a large number of sized openings. The benefit of multipart systems is that smaller individual covers can be easily lifted to provide access to larger openings.

Some common applications include container ports, airport pavements, lift motor room floors, and where access to large industrial equipment, large electrical pits, pump wells, and transformers is required. However, despite their easy-lifting design, multipart covers can be tricky to install. This is largely due to the multiple parts which need to be correctly identified, prepared and aligned. If you wish to install a multipart access cover system, the simplest way of going about it is to follow our short tutorial.

Some key points to remember:

- Load Class - select correct cover and rebate to suit load class. The frame is designed to be fully supported by a bed of concrete

- Install with cover positioned in the frame

- Decorative edging may require a deeper rebate than specified, depending on finish level

- Tiles or pavers should be fully restrained and bonded to the concrete bed. An epoxy mortar is recommended

- Cover and frame are a matching pair and should not be switched as fit and seal may be compromised

- Ensure that there is no rock between cover and frame otherwise seal will be compromised and service life will be reduced

- Concrete of a minimum strength of 32MPa and minimum aggregate of 12mm is recommended

- Position so that removal of cover is not obstructed by a wall, kerb etc.

- Applications where back pressure is expected may require additional reinforcing to hold the frame and cover in position.

- Urbanfil / Pavermate covers are to be filled to a minimum concrete depth of 45mm, with minimum strength 32MPa and minimum cement content of 400 kg/m3. Concrete is integral to the strength of the cover.

If you require help planning and designing your own access cover system, our ACCTRIX™ programme enables you to calculate a choice of 5 systems based on your enclosure's size and load class requirements. ACCTRIX™ generates specifications and pricing to make your decision easy. However, if you require further assistance planning your system, don't hesitate to contact the team at ACO.

|

Sloped Trench Drains for Sports

Sloped Trench Drains for Sports Heelsafe Anti-slip Grates and Covers

Heelsafe Anti-slip Grates and Covers Balcony Drains for Sydney Apartments

Balcony Drains for Sydney Apartments Bridge Stormwater Drainage with

Bridge Stormwater Drainage with Custom Sloped Channel Drainage for Pools

Custom Sloped Channel Drainage for Pools Slip-Resistant Push-Fit Drainage for

Slip-Resistant Push-Fit Drainage for Grease Management and Drainage for

Grease Management and Drainage for Freestyle Architectural Drain Grates -

Freestyle Architectural Drain Grates - Surface Water & Cable Management of Rail

Surface Water & Cable Management of Rail KerbDrain Trench Drain System for Camden

KerbDrain Trench Drain System for Camden Trench Drain Shape and Hydraulic

Trench Drain Shape and Hydraulic Multipart Access Cover Installation

Multipart Access Cover Installation Drainage for Road Infrastructure by ACO

Drainage for Road Infrastructure by ACO Steel Production for Construction Across

Steel Production for Construction Across Surface Drainage for Construction by ACO

Surface Drainage for Construction by ACO Non-Slip Drainage for Public Area from

Non-Slip Drainage for Public Area from Hygienic Grease Management for

Hygienic Grease Management for Grease Management and Drainage System

Grease Management and Drainage System Trench Drains for Transport

Trench Drains for Transport New Trench Drain Technical Handbook by

New Trench Drain Technical Handbook by