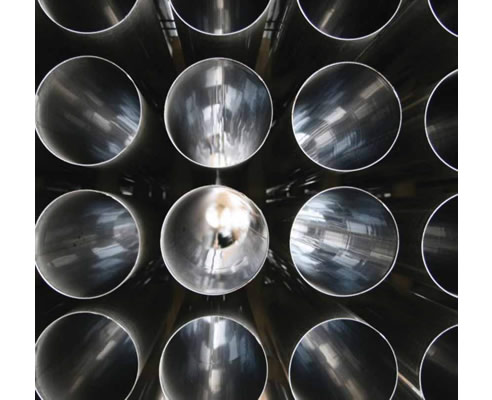

Stainless Steel Pipe System Specifications from ACO Polycrete ACO Pipe stainless steel pipe systems: The right specification. The resilience of stainless steel offers a major advantage over cast iron and PVC above ground, as well as below. If a truck reverses into a cast iron or PVC downpipe, the impact may well fracture the pipe, while stainless steel is more likely to suffer an indentation without fracture, that can be more economically and conveniently fixed. All of these points underline the fact that stainless steel drainage products reduce risk for all parties, from the manufacturer to the supplier, the specifier, the installer, and, finally, the end-user. However, improving the specification of pipework and drainage systems for healthcare environments is not simply a matter of adding some stainless steel components to your system and giving the matter no further thought. For example, mixing materials can pose significant problems, even when one of those materials is stainless steel, and good engineering practice dictates that different metallic materials should not be used in direct contact. A poorly specified system that, for example, uses cast iron or galvanised steel as a hidden component connected to a visible stainless steel drainage grating, chosen for cosmetic effect, can be a false economy as the contact between those two different metals will result in galvanic corrosion. Similarly, if you are designing a system in which acids are present, you need the help and advice of an experienced manufacturer that understands the corrosive effect of those acids on metals; there are over 150 grades of stainless steel, and an expert supplier can tailor the materials used to best resist the corrosive effect of each given acid. Even 316 stainless steel, which contains molybdenum, and offers an even more resilient option than the more commonly used grade 304, can be vulnerable to certain chemicals, such as hydrochloric acid (HCI) and sulphuric acid (H2SO4). The right specification can, in fact, only be made by first carefully considering the drainage performance requirements of a hygiene-critical environment and understanding the corrosive nature of the liquids that the system will be handling. Informed material selection can only be made using the right criteria and an awareness of the limitations, and this is best achieved by working with a supplier that understands the issues and can offer expert advice. Making a checklist In all applications, but particularly within the healthcare sector, a corrosion resistance checklist will help ensure that no crucial issue is overlooked during the specification process. A checklist needs to include questions such as:

|

1300 765 226 Emu Plains, NSW, 2750

|

Sloped Trench Drains for Sports

Sloped Trench Drains for Sports Heelsafe Anti-slip Grates and Covers

Heelsafe Anti-slip Grates and Covers Balcony Drains for Sydney Apartments

Balcony Drains for Sydney Apartments Bridge Stormwater Drainage with

Bridge Stormwater Drainage with Custom Sloped Channel Drainage for Pools

Custom Sloped Channel Drainage for Pools Slip-Resistant Push-Fit Drainage for

Slip-Resistant Push-Fit Drainage for Grease Management and Drainage for

Grease Management and Drainage for Freestyle Architectural Drain Grates -

Freestyle Architectural Drain Grates - Surface Water & Cable Management of Rail

Surface Water & Cable Management of Rail KerbDrain Trench Drain System for Camden

KerbDrain Trench Drain System for Camden Trench Drain Shape and Hydraulic

Trench Drain Shape and Hydraulic Multipart Access Cover Installation

Multipart Access Cover Installation Drainage for Road Infrastructure by ACO

Drainage for Road Infrastructure by ACO Steel Production for Construction Across

Steel Production for Construction Across Surface Drainage for Construction by ACO

Surface Drainage for Construction by ACO Non-Slip Drainage for Public Area from

Non-Slip Drainage for Public Area from Hygienic Grease Management for

Hygienic Grease Management for Grease Management and Drainage System

Grease Management and Drainage System Trench Drains for Transport

Trench Drains for Transport New Trench Drain Technical Handbook by

New Trench Drain Technical Handbook by