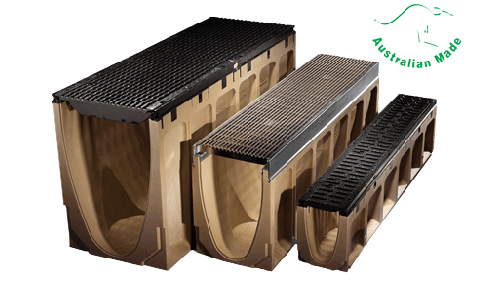

Commercial Modular Trench Drains from ACO 8 Reasons Why Designers Specify and Contractors Choose the World's Best Commercial Trench Drain System ACO's trench drains are highly regarded in the construction industry for their drainage effectiveness, efficiency, durability and choice of architectural grates. Here are 8 reasons why designers specify the world's best commercial trench drain system. 1. ComplianceACO's drainage systems meet both Australian and international standards, AS3996 (Access Covers and Grates) and EN1433 (Drainage channels for vehicular and pedestrian areas) respectively. Additionally, all grates have been load tested and NATA certified. ACO has NATA accreditation (No.15193) for its testing laboratory and, for its standard and custom grates, can provide NATA certified test reports to both AS3996 and EN1433. 2. Materials and DesignMaterials used to manufacture ACO's drainage products are selected carefully for their superior durability in Australian conditions, making systems suitable for all applications. This includes light-duty urban environments to busy motorways and heavy-duty industrial applications. Polycrete® Channels, grates and edge rails are manufactured from a variety of robust, durable and aesthetic materials designed to suit a large number of application environments and project specifications. ACO offers a suite of channel and grate options depending on the intended application. Polycrete® is ACO's trademark for polymer concrete castings made in Sydney from a manufacturing process that is highly regulated by batch testing and stringent quality practices. Polymer concrete is a composite that comprises a polyester resin binder reinforced by mineral aggregates and fillers. The resulting castings are strong, compact and impervious to moisture as well as resistant to chemical and biological attack making Polycrete® Channels the most precision manufactured and durable product solution on the market. The edge rails are the exposed edges of the trench, which secure the grate into position, and because they are exposed to the same loads as the grate, they are robust and integrally cast. Edge rails are fitted with interlocking lugs to prevent the longitudinal movement of grates, a common failure mode for inferiorly designed trench drains with ill-fitting rails. ACO's rails are manufactured from rolled galvanised steel or stainless steel or cast ductile iron for optimum durability. Finally, a trench drain's design life is heavily influenced by how well it keys into a slab or pavement. This is critical for load transference and uniform loading stress distribution. ACO's Polycrete® Channels incorporate a mechanical keying design comprising deep pockets and large structural ribs. This ensures that the drain when installed correctly, works homogeneously with its encasement surrounds for the intended design life of the pavement or slab. 3. Hydraulic EfficiencyACO's trench drains are uniquely designed with a 'V' profile. This is very different to the typical 'U' shape or flat bottom drain characteristically supplied in the industry. 'U' shaped drains, whilst easy to manufacture, are prone to sedimentary build up as the geometry tends to minimise water depth and therefore water velocity. Water has a tendency to move under the influence of its own weight. The deeper the water, the quicker it moves. In stark contrast, ACO's trench drains are designed to maximize water depths. Oddly enough, the benefits are realised during (the more common) minor rainfalls events, where water depths (i.e. velocities) need to be maximized to produce a better self-cleaning effect. This is extremely important because it ensures drains are sediment-free in preparation for the next major storm event that produces the peak flows. The drainage is further improved by polymer concrete's smooth surface, which enables fluids to flow at their optimum speed with less friction. Flat and level pavements are the safest to walk or drive on but extremely difficult to drain. This is because water can only flow efficiently downhill. Standing water can be dangerous or at least be a nuisance. To solve this, ACO's trench drains comprise channels with continuously sloped inverts for up to 40 metres in length with a 0.5% built-in slope, in a range of widths and load classes. This allows designers to only incorporate simple, safe and subtle falls in their pavements as opposed to complex falls required for non-sloping channels or isolated grated pits. 4. Easy InstallationACO's newest trench drain installation device allows for quicker installation. The device also removes any uncertainty and instability that once existed with poorly skilled contractors when installing modular drains. Channel elements can also be set up quickly and securely whilst allowing for single concrete pour operations. ACO's innovative design was developed in conjunction with its new generation trench drain to ensure perfect alignment of joints and channel heights. 5. Boltless GratesUnlike conventional trench drains, ACO's systems contain no bolts and provide secure locking while enabling rapid removal and replacement of grates for quick and easy installation and maintenance. Light to medium duty grates is secured with the Quicklok boltless locking device. A nylon stud is factory-fitted to the grate, allowing it to snap tight into a bar positioned across the channel. ACO's heavy duty grates are secured with PowerLok. This locking system doesn't require a locking bar and is surrounded by the anti-shunt lugs (mentioned previously) positioned in the edge rail to prevent longitudinal movement from traffic loads. 6. Heelsafe® AntislipACO believe that small slotted grates and slip resistance should go hand in hand. Compliant to a number of Australian Standards for pedestrian, wheelchair, bicycle and cane use, ACO's slip resistant grates are available in a range of designs and materials to suit individual application requirements. There are 9 different types of foot-friendly grates to suit all projects. Each grate has been slip rated to AS 4586 (Slip resistance classification of new pedestrian surface materials) to give pedestrians assurance underfoot 7. Technical ServicesACO has invested heavily to technically support its product lines. Staffed by qualified engineers and equipped with purpose-written computer software, a design service is offered as a no-obligation service and is backed up with extensive, high-quality information. ACO's Technical Services Department can offer professionally presented documented advice on water management layouts, hydraulics, correct product selection, through to advice on installation and maintenance. ACO has also conducted extensive water intake tests on all of its grates at the Water Research Laboratory, UNSW. Comprehensive research and development, both independently, and in conjunction with leading academic institutions and research bodies, have been key to the ACO's success. 8. Customer ServiceACO's objective is to provide a 'right-first-time' policy to complement our unmatched technical support and innovative culture. When you deal with an Australian manufacturer, you can expect world-class customer service without delays. ACO continually trains and develops its employees so they are empowered to not only provide the customer with the right information but also deliver it with the right attitude. ACO's sales force offers a comprehensive support service for specifiers and installers. Its internal telesales offices deal with incoming enquiries and orders. Stocks of the product are located at strategic locations in all major cities, which are constantly being replenished from ACO's manufacturing facility in Sydney. Logistics and distribution teams are responsible for supplying orders to customers correctly and on time. For more information, visit www.acoaus.com.au today.

|

1300 765 226 Emu Plains, NSW, 2750

|

Sloped Trench Drains for Sports

Sloped Trench Drains for Sports Heelsafe Anti-slip Grates and Covers

Heelsafe Anti-slip Grates and Covers Balcony Drains for Sydney Apartments

Balcony Drains for Sydney Apartments Bridge Stormwater Drainage with

Bridge Stormwater Drainage with Custom Sloped Channel Drainage for Pools

Custom Sloped Channel Drainage for Pools Slip-Resistant Push-Fit Drainage for

Slip-Resistant Push-Fit Drainage for Grease Management and Drainage for

Grease Management and Drainage for Freestyle Architectural Drain Grates -

Freestyle Architectural Drain Grates - Surface Water & Cable Management of Rail

Surface Water & Cable Management of Rail KerbDrain Trench Drain System for Camden

KerbDrain Trench Drain System for Camden Trench Drain Shape and Hydraulic

Trench Drain Shape and Hydraulic Multipart Access Cover Installation

Multipart Access Cover Installation Drainage for Road Infrastructure by ACO

Drainage for Road Infrastructure by ACO Steel Production for Construction Across

Steel Production for Construction Across Surface Drainage for Construction by ACO

Surface Drainage for Construction by ACO Non-Slip Drainage for Public Area from

Non-Slip Drainage for Public Area from Hygienic Grease Management for

Hygienic Grease Management for Grease Management and Drainage System

Grease Management and Drainage System Trench Drains for Transport

Trench Drains for Transport New Trench Drain Technical Handbook by

New Trench Drain Technical Handbook by