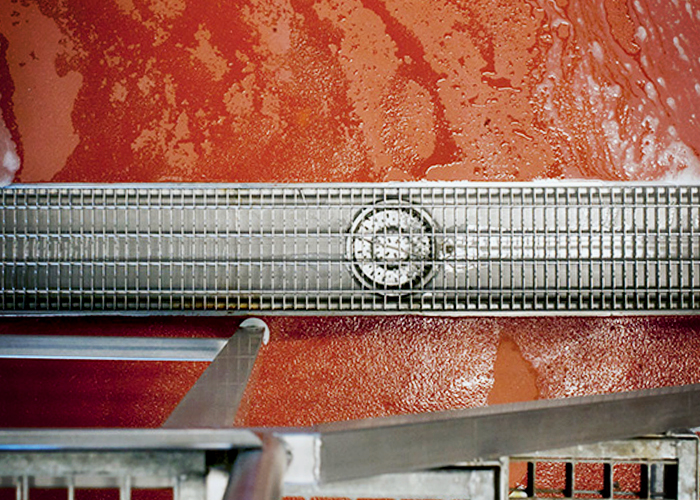

Drainage to Match Improved Production Capabilities from ACO Upgrading your drainage to match your improved production capabilities Understandably manufacturers focus on upgrading equipment and technologies when they are gearing up for increases in demand or planning for future growth. Much time is spent on areas such as the specification of new processing equipment, re-designing the layout of an existing production facility so it can accommodate new machinery, and the creation of zones to mitigate the risk of cross contamination or make processing and packing easier. Hygiene, health and safety are of course key considerations, however where drainage has a major role to play in optimising hygiene, cleanability, and related costs, it's easy for the facility's drainage system to become an after-thought. What problems does this cause? A failure to consider the drainage system at the initial planning stage can cause numerous issues:

What's the solution? Prevention of this type of issue is not overly complicated - drainage simply needs to be considered at the initial planning stages of any factory redevelopment. We have five key tips to make this process as easy and effective as possible:

At ACO we are committed to helping the food and beverage drinks industry put hygiene first. We have extensive experience of working with leading manufacturers and some of world's largest food and beverage companies. If you're currently planning an upgrade, or simply interested in learning more, please get in touch.

|

1300 765 226 Emu Plains, NSW, 2750

|

Sloped Trench Drains for Sports

Sloped Trench Drains for Sports Heelsafe Anti-slip Grates and Covers

Heelsafe Anti-slip Grates and Covers Balcony Drains for Sydney Apartments

Balcony Drains for Sydney Apartments Bridge Stormwater Drainage with

Bridge Stormwater Drainage with Custom Sloped Channel Drainage for Pools

Custom Sloped Channel Drainage for Pools Slip-Resistant Push-Fit Drainage for

Slip-Resistant Push-Fit Drainage for Grease Management and Drainage for

Grease Management and Drainage for Freestyle Architectural Drain Grates -

Freestyle Architectural Drain Grates - Surface Water & Cable Management of Rail

Surface Water & Cable Management of Rail KerbDrain Trench Drain System for Camden

KerbDrain Trench Drain System for Camden Trench Drain Shape and Hydraulic

Trench Drain Shape and Hydraulic Multipart Access Cover Installation

Multipart Access Cover Installation Drainage for Road Infrastructure by ACO

Drainage for Road Infrastructure by ACO Steel Production for Construction Across

Steel Production for Construction Across Surface Drainage for Construction by ACO

Surface Drainage for Construction by ACO Non-Slip Drainage for Public Area from

Non-Slip Drainage for Public Area from Hygienic Grease Management for

Hygienic Grease Management for Grease Management and Drainage System

Grease Management and Drainage System Trench Drains for Transport

Trench Drains for Transport New Trench Drain Technical Handbook by

New Trench Drain Technical Handbook by