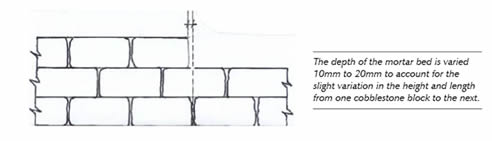

Tips for Laying Cobblestone Blocks from Timbercrete Timbercrete's Cobblestone blocks are the most popular of the Timbercrete range. They feature a smooth curved face with a river stone / cobble stone appearance. These bricks and blocks will have slight variation in size which is intentional. The mortar joints accommodate this variation by ranging 10mm to 20mm thick. The professional training of a bricklayer will prompt them to reject a proportion of Timbercrete blocks due to the irregularities in size, surface or colour. If you are building with Timbercrete blocks, it is vital that your builder is made aware of the significant differences from the conventional concrete bricks which are all identical in size. The correct thickness of horizontal mortar joints will be determined by the bricklayers string line. By selecting shorter or longer blocks, a bricklayer will be able to maintain straight and centre located perpendicular lines. The mortar bed should not be a perimeter shell as with traditional hollow core concrete blocks. All Timbercrete bricks need to have a solid, full bed of mortar, in both horizontal and vertical joints. There are 2 reasons why this is important: 1. It ensures maximum bond and load bearing strength. 2. It prevents cavaties in which water can pool and ultimately leak through the mortar joint. It's also important to remember that the longer the block, the greater the cobblestone slump and more mortar will be needed. The same incremental benchmarks should be followed between doors and windows when setting out the job. Here are some tips on laying your irregular cobblestone bricks and blocks. 1. Run your string line on the inside of the wall, rather than the outside. This will ensure the inside will be more accommodating for the cornice, skirting or rendering. It will also give the outside wall a little more character. 2. Flatter faced blocks, without the cobblestone curves, can be used on the top and bottom courses as well as around window and door openings. This ensure flat internal surfaces to abut cornices, door and windoe frames and skirting. A proportion of flatter blocks is send with each Timbercrete Cobblestone order. 3. If you have specialty blocks, these should only be used in positions where they are required to perform their specific function. These specialty blocks are those with grooves, slots or cut outs. As a general rule these should not be used in general block laying otherwise they may run short when needed. 4. All blocks have a 'rough' bottom and a 'smooth flat' top which is a result of the manufacturing method. Ensure the smooth surface is always facing upwards. This provides a flat smooth surface for the string line and spirit level. 5. As Cobblestone blocks and bricks are hand crafted they vary slightly in height, width and length. This variation creates the unique Cobblestone appearance. The bricklayer should appreciate that the variation in block dimensions and shapes is intentional and is compensated by the varying thickness of mortar joints. Also, some Timbercrete blocks feature split faces, air bubble pock marks, and various other surface and colour irregularities. These are all standard features which are purposely created. 6. Some bricks and blocks will have a slightly different colour from batch to batch, especially if there are several months of separate consecutive orders. To eliminate this, you may wish to order the entire batch at one time. If this isn't possible, keep a few pallets of bricks of blocks aside and blend them with the newly ordered batch when they arrive.

|

03 9752 2989 Unit 4, 23 Kevin Avenue, Ferntree Gully, VIC, 3156

|

Sandstone Bricks & Blocks for Building

Sandstone Bricks & Blocks for Building Sustainable Building Bricks & Blocks

Sustainable Building Bricks & Blocks Timber Waste Masonry and Concrete

Timber Waste Masonry and Concrete Specialty Building Blocks | Ligna Group

Specialty Building Blocks | Ligna Group Wet Cast Pavers | Ligna Group

Wet Cast Pavers | Ligna Group Bricks with High Fire Resistance | Ligna

Bricks with High Fire Resistance | Ligna Sustainable Vessel Bodies | LignaStone

Sustainable Vessel Bodies | LignaStone High Performance Outdoor Pizza Oven |

High Performance Outdoor Pizza Oven | Handcrafted Timeless Bricks | LIGNASTONE

Handcrafted Timeless Bricks | LIGNASTONE Eco Friendly Bricks and Blocks South

Eco Friendly Bricks and Blocks South Sustainable Masonry Construction |

Sustainable Masonry Construction | Insulating Bricks and Blocks |

Insulating Bricks and Blocks | High Fire Resistance Bricks Now in

High Fire Resistance Bricks Now in Building with Timbercrete Bricks and

Building with Timbercrete Bricks and Sandstone Bricks 360 Series |

Sandstone Bricks 360 Series | Timbercrete Bricks and Blocks

Timbercrete Bricks and Blocks Smoothstone Sandstone Bricks |

Smoothstone Sandstone Bricks | Thermal Brick House South Australia |

Thermal Brick House South Australia | Cobblestone Bricks Thermally Efficient |

Cobblestone Bricks Thermally Efficient | Environmentally Friendly Building Bricks

Environmentally Friendly Building Bricks