Anyone working within a laboratory environment will know the critical importance of a correctly designed and safely operated fume exhaust system. Typical components of a fume exhaust system include fume cupboards, airflow valves and ductwork, exhaust fans and rooftop vents. Potentially harmful gases and particulates are drawn out of the room, diluted with fresh makeup air and expelled into the atmosphere through exhausts situated on top of the roof.

AS/NZS 2243.8:2014 provides the requirements for fume cupboards relating to their safety and performance. It also comes with recommendations and procedures for their selection, installation, testing and use.

A safe and efficient fume exhaust system depends on the following design parameters:

The revision AS/NZS 2243.8:2014 comprised several significant changes relevant to the design, manufacture, installation and maintenance of fume cupboard exhaust systems. The necessity for a "Risk Assessment" was added to the standard (it was already part of other, companion standards) and tests that determine the performance of fume cupboards, were clarified to ensure indoor and outdoor air quality.

The standard emphasises the importance of appropriate manifolding, and specifies the fan type that is needed to achieve optimal performance over the full operational range. All fans in a manifolded system should be of the same size, including an equally sized "redundant" fan.

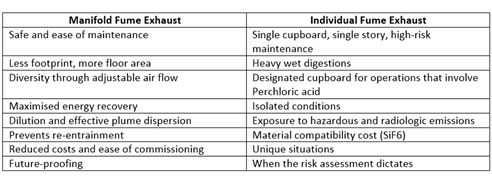

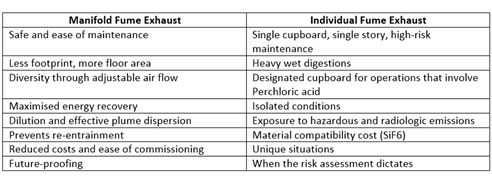

Decades of international experience has proven that a manifold laboratory fume exhaust offers several advantages to its clients; such as improved safety, cost and energy reduction, and exhaust performance.

The changes to AS/NZS 2243.8:2014 were based on international practices Labs 21, and I2SL (US EPA, US Dept. of Energy), ANSI Z9.5: 2012, ASHRAE, AS 2243.8

Here are some of the key benefits of a manifold laboratory system;

Increase fume dilution

The combined air flows from all of the hoods effectively dilute chemical spills or odours' coming from one hood, from the moment it joins the manifold and well before it reaches the exhaust fan outlet. Increased fume dilution makes the stream less hazardous. Reduced concentration of vapours is beneficial with surrounding residents and workers.

Enhanced personnel safety

Safeguarding staff is one important consideration. In a manifold laboratory fume exhaust design, a built-in backup fan is on standby and automatically operates should there be a system failure. This improves business continuity in the lab and staff safety in the lab and on the roof.

Augmented redundancy

Reliable "up-time" is a critical need for research facilities and laboratories, many of which have extended hours of operation. Manifolded laboratory fume exhaust fans utilize "N+1" redundancy to assure full operational at all times, unlike individual systems where a single exhaust failure will force closure of a laboratory. Planning for redundancy must begin in the pre-planning or pre-design phase.

Improved design flexibility

To respond to changes in research, advancements in technology, and cater to personnel needs; laboratory facilities must meet and accommodate these changes. Manifold fume exhaust systems are flexible and can be altered over time, allowing a level of future proofing that is not possible with individually ducted systems. The need for total "riser" space is reduced with a manifolded system, further enabling layout flexibility and increased floor space for laboratories.

Probable energy recovery

Manifold fume exhaust systems may decrease required total fan power with their highly efficient motors and impellers. They provide a modulated airflow and consume less total power to effectively disperse exhaust plumes.

Fans can be staged and controlled with dedicated systems controllers combined with VSDs and are compatible with heat exchange or energy recovery units.

Advantages of Manifold Laboratory Fume Exhaust System

The Safe, Compliant and Correct Way to Manifold Laboratory Fume Exhaust System

AS/NZS 2243.8 separates general exhaust from fume exhaust systems for safety and overall energy conservation. This differs from general overseas practice - where both streams are commonly combined. Thus there are unique factors to consider for the application of manifold laboratory fume exhaust systems in Australia and NZ. They include exhaust stream compatibility, the location and number of fume hoods, and compliance to codes and standards. It is not advisable to drop below diversity values of about 80% for safe performance. In fact, designs that use 100% diversity do not cost much more in initial capital cost, is equivalent in running costs, and eliminates many potential performance/safety issues over the life of the building and plant.

Strobic Air Tri-Stack™ Fume Exhaust Systems from Camfil Airepure

Strobic Air Tri-Stack™ offers a cost-effective solution to industrial pollution control, re-entrainment and odour control. It conforms to the following international standards: AS/NZS 2243.8, AS 1668.2, ANSI Z9.5, ASHRAE 110, and NFPA 45.

The following points cover the safe, correct and compliant way to manifold Strobic Air Tri-Stack™:

- They maintain exhaust velocity under all conditions

- As manifold systems will have more than one fan, isolation dampers for inactive fans will be needed

- Vortex breakers from plenums improve performance and reliability

- Pre designed plenum systems are highly cost effective

- Reliable, integrated static based control systems are required so control systems need to be integrated and fast rather than via the BMS controller.

- Duct stability to static is required under all operating conditions

- Adequate balancing of all arms and extensions is needed

Tri-Stack™ Smart System

Tri-Stack™ Smart System keeps safe ventilation levels while optimising the reduction of carbon footprint and energy consumption of the facility. The Smart System primary functions are to control lab inlet flows and face velocities, while maintaining or exceeding the minimum safe outlet velocity. The Smart System also aids maintenance by "bumping" redundant fans, logging critical parameters and calling into action the redundant fan to maintain lab safety, if conditions demand it.

Strobic Air Tri-Stack™ manifold fume exhaust systems from Camfil Airepure upholds safety, operational diversity, and lowers energy consumption essential in achieving greener buildings.

Camfil Airepure is the official distributor of Strobic Air Tri-Stack™ roof exhaust fans. Our technical and engineering staff are equipped with years of experience in planning new or retrofit roof exhaust fan systems.

Book a consultation with Camfil Airepure today.

AIRAH Product of the Year Kaire®

AIRAH Product of the Year Kaire® HEPA Box-type Compact Filters by Camfil

HEPA Box-type Compact Filters by Camfil Dust & Fume Collection Systems - Gold

Dust & Fume Collection Systems - Gold Compact Dust Collectors - Quad Pulse

Compact Dust Collectors - Quad Pulse High-temperature HEPA Filters from

High-temperature HEPA Filters from CleanSeal Terminal HEPA Housings from

CleanSeal Terminal HEPA Housings from Safe Change HEPA Filter Containment

Safe Change HEPA Filter Containment HEPA Panel Filters - Megalam by Camfil

HEPA Panel Filters - Megalam by Camfil Terminal HEPA Filter Housings -

Terminal HEPA Filter Housings - Energy Saving Ventilation Filters -

Energy Saving Ventilation Filters - In-room Air Cleaners from Camfil

In-room Air Cleaners from Camfil Filters for Food Processing - ProSafe

Filters for Food Processing - ProSafe Energy Efficient HVAC Bag Filters -

Energy Efficient HVAC Bag Filters - Chemical Media for Gaseous Filtration

Chemical Media for Gaseous Filtration Air Filtration of Commercial Buildings

Air Filtration of Commercial Buildings Manifolded Fume Exhaust System for UNSW

Manifolded Fume Exhaust System for UNSW Environmental Air Quality Control with

Environmental Air Quality Control with Disposable Air Filters from Camfil

Disposable Air Filters from Camfil Commercial Air Filtration for Kitchen

Commercial Air Filtration for Kitchen Efficient Air Filtration Systems with

Efficient Air Filtration Systems with