Commercial air filtration is a safety requirement and a valuable part of a reliable kitchen exhaust design that spans across a wide variety of commercial kitchen applications. Hotels, restaurants and other food outlets offer different types of cuisine, leading to varying amounts of grease, odour, smoke, moisture and particles. Although air emissions coming from food preparation may not contain toxic substances, smoke and related odours can become a nuisance to people, surrounding neighbourhoods and local city councils.

Complying with the broad standards and parameters in kitchen exhaust design might be complex due to the diverse range of sites, applications and environments. Hence, it is essential for major industry specifiers and business owners to work with a company that has in-depth commercial air filtration knowledge.

Camfil Airepure helps to improve the quality of air and control odour issues with their broad range of commercial air filtration solutions. Camfil Airepure's in-house skilled engineers and consultants are also knowledgeable with the local and international safety standards that reduce fire risks and exhaust odours.

AS/NZS 1668.1 (The use of ventilation and air conditioning in buildings - Fire and smoke control in buildings)

Section 6.2.9, in accordance with UL 1046, specify the need to incorporate a device that prevents the spread of flame in the kitchen exhaust design. This is applicable if the exhaust duct work is longer than 10 metres and there is a flame in the cooking process (solid fuel or gas).

AS/NZS 1668.2 (The use of air conditioning and ventilation in buildings - Mechanical ventilation)

This is the most commonly referenced standard, which requires grease filters or oil removing devices to be integrated into the kitchen exhaust design. The standard also reiterates the need for non-combustible filter media and modules. Filter media must be removable by hand for cleaning purposes, should an in-situ washing system be not available.

UL 1046 (Standard for Grease Filters for Exhaust Ducts)

Grease filters must have the following abilities:

a. Limit the projection of flames downstream when subjected to upstream flames after having been loaded with grease-rich exhaust

b. Drain collected grease without falling back onto the cooking surface

Timing is another important factor that is often overlooked by specifiers and business owners. It is difficult and rather expensive to retrofit for kitchen exhaust hood filters once the commercial kitchen is already built. Hence, incorporating the right kitchen exhaust design and associated filter media are best done at the beginning of construction.

Safe, Compliant, and Correct Design Considerations for Kitchen Exhaust Hood Filters

The airflow recommended for kitchen exhaust hood filters, as specified in AS/NZS 1668.2, is at a minimum rate depending on the size, type of hood, and the cooking equipment under the hood. Efficient treatment of kitchen exhaust design involves duct air temperature below 50°C with low contaminant concentration. Designing kitchen exhausts with the correct airflow rate enhances the kitchen's ventilation and decreases the risk of inefficient downstream treatment systems.

Kitchen exhaust hood filters are designed for the following purposes:

1. Particle Filtration

Remove excess hot air and introduce clean air for a safe and comfortable work condition. It also reduces the amount of grease and oil in the exhaust duct.

2. Fire Safety

Prevent flames from entering the exhaust duct. It also inhibits fat residue buildup and clogging of air inlets that can increase the risk of fire.

The primary goal of the kitchen exhaust system is to ensure that no smoke, grease or offensive odour will be released into sensitive environments. Choosing the right exhaust design is based on the contamination level, and airflow rate required for a particular application.

Camfil Airepure offers Captrate® Solo is a single stage, high-efficiency hood filter; designed and manufactured to comply with Australian Standards. Using an advanced technology, Captrate® Solo enhances the safety and cleanliness of commercial kitchen exhaust hood filters.

Here are the reasons why Captrate® Solo is the new generation kitchen exhaust hood filter.

Single Stage Baffle Filter for Commercial Kitchen Exhaust Design

Captrate® Solo captures and eliminates a high percentage of the total grease particulate emissions produced during cooking in commercial kitchen operations. Captrate® Solo features a unique S-Baffle design and fits into standard 50mm deep hood channels for optimum filtration efficiency in a single hood device application.

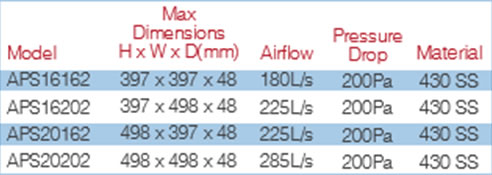

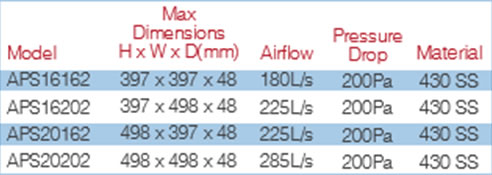

Captrate® Solo is highly resistant to corrosion and oxidation at elevated temperatures. It filters 90% of grease particles at seven microns in size with the following recommended airflow rate.

Baffle style filters work by forcing the grease-filled air to quickly and repeatedly change direction as it rises through the filter. Since the grease particles cannot quickly change direction, they end up being condensed to the metal blades and drain into the filter tray.

The self-draining ability of baffle-style kitchen exhaust hood filters minimises the spread of flames, should a fire break out on top of the cooking surfaces, because the grease or other combustible substances, are not retained on the filter face.

Reduced Operating Costs

Captrate® Solo can catch two to four times the weight of grease as compared to other baffle filters. It also reduces upkeep costs by minimising the frequency of hood and duct work cleaning. Captrate® Solo prolongs the service life of particle and odour filtration within downstream air purification systems.

Designed to Reduce Fire Risks

Captrate® Solo are designed and manufactured to meet the criteria of UL 1046 (Standard for Grease Filter), NSF-2 (Commercial Food Equipment Standards), and NFPA 96 (Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations). These standards cover a broad range of stringent kitchen exhaust dust, ventilation control and fire protection.

Captrate® Solo kitchen hood filters are designed to:

1. Remove atomised grease from airstream

2. Limit the projection of flames downstream when subjected to upstream flames after having been loaded with grease-rich exhaust

3. Be self-draining so the oil/grease load does not fall back onto the cooking surface

4. Have the structural integrity to quickly facilitate routine commercial use, handling, cleaning, and maintenance

Captrate® Solo also prevents the spread of flames in accordance to clause 6.2.9 of AS/NZS 1668.1.

Seamless Removal and Cleaning of Modules

The highly efficient, single kitchen exhaust hood filter is made up of 430 SS, a low-carbon, plain chromium ferritic stainless steel. The 430 SS is a robust yet lightweight component often used for kitchen grade utensils and equipment. In-house cleaning of filter media is done by just removing the filters from the exhaust canopies and soaking them overnight in a commercial degreaser or by washing them in a dishwasher.

Odour Control in Kitchen Exhaust Design

A well-designed kitchen exhaust system involves removing particulates like grease and smoke to a high level before removing the odour. Activated carbons are the material of choice for most odour abatement systems. However, adequate protection of activated carbon is necessary to ensure extended life service, unnecessary replacement costs on activated carbon components, and optimum odour removal performance.

Air filtration devices that remove a minimum of 95% of particles at 0.3 microns are therefore used in conjunction with activated carbons. The following are the most common type of odour control devices used in commercial kitchens:

1. Multi-Staged Filter Pack

Multi-staged filter packs are suitable for use in commercial kitchen application with a small to moderate contaminant loading. This system offers cheaper upfront costs but with higher operating maintenance costs due to static and filter change outs. Changing of filter media can be reduced by pairing this with a high efficiency hood filter or UV-C lamps before the filter pack.

The Camfil Airepure KAIRE Unit is a multi-stage filter pack composed of the following components:

a. Pre-filters (G4 filter) that remove 45% of total grease and smoke

b. Intermediate filters (F7-rated multi-pocket filter) eliminates 45% of contaminants, with a medium filter lifespan

c. Final filters (H11-rated mini-pleat or HEPA filter) remove the remaining 10% contaminants which is mainly smoke.

d. Activated carbons for efficient odour removal capacity

2. ESPs (Electrostatic Precipitators)

Electrostatic Precipitators are suited for commercial kitchens with higher contaminant loading. ESPs use electrostatic charges to ionise particles before collection on plates of the opposition charge. For an optimum odour control, the plates must be cleaned on a regular basis to remove grease and trapped smoke particles. An ESP with automatic cleaning is more cost effective than manual clean ESP's, which have higher operating costs than multi-stage filter packs.

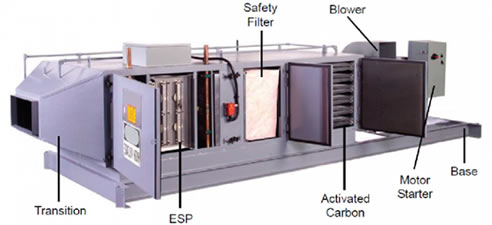

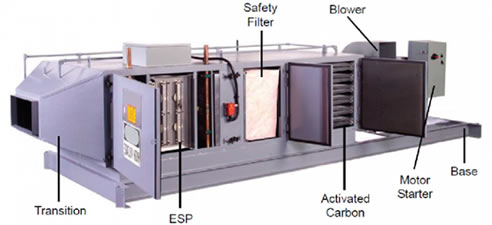

Camfil Airepure's PowerClean large scale auto-wash ESP contains the following components:

a. Pre-filters that capture large particles that may short-circuit the ESP cell

b. ESP cells, which remove smoke and grease contaminants. It requires regular cleaning depending on the kitchen load

c. Programmable auto-wash and fan dry function to keep the ESP running efficiently

d. Safety bag filter (F6 or F8) that protects the activated carbon

e. Activated carbon for maximum odour removal capacity

A commercial kitchen has various needs and purposes. Identifying these factors help determine the appropriate commercial air filtration and design parameters ideal for an efficient, long-lasting and cost-effective kitchen ventilation.

Consult with Camfil Airepure for your next kitchen exhaust design project today.

AIRAH Product of the Year Kaire®

AIRAH Product of the Year Kaire® HEPA Box-type Compact Filters by Camfil

HEPA Box-type Compact Filters by Camfil Dust & Fume Collection Systems - Gold

Dust & Fume Collection Systems - Gold Compact Dust Collectors - Quad Pulse

Compact Dust Collectors - Quad Pulse High-temperature HEPA Filters from

High-temperature HEPA Filters from CleanSeal Terminal HEPA Housings from

CleanSeal Terminal HEPA Housings from Safe Change HEPA Filter Containment

Safe Change HEPA Filter Containment HEPA Panel Filters - Megalam by Camfil

HEPA Panel Filters - Megalam by Camfil Terminal HEPA Filter Housings -

Terminal HEPA Filter Housings - Energy Saving Ventilation Filters -

Energy Saving Ventilation Filters - In-room Air Cleaners from Camfil

In-room Air Cleaners from Camfil Filters for Food Processing - ProSafe

Filters for Food Processing - ProSafe Energy Efficient HVAC Bag Filters -

Energy Efficient HVAC Bag Filters - Chemical Media for Gaseous Filtration

Chemical Media for Gaseous Filtration Air Filtration of Commercial Buildings

Air Filtration of Commercial Buildings Manifolded Fume Exhaust System for UNSW

Manifolded Fume Exhaust System for UNSW Environmental Air Quality Control with

Environmental Air Quality Control with Disposable Air Filters from Camfil

Disposable Air Filters from Camfil Efficient Air Filtration Systems with

Efficient Air Filtration Systems with Airborne Containment Solutions for PC3

Airborne Containment Solutions for PC3