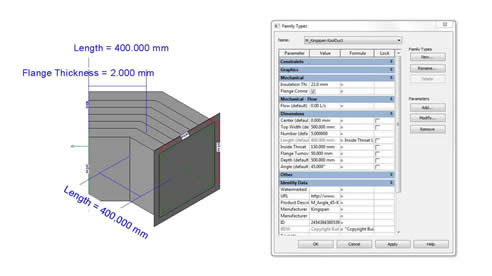

Pre-Insulated Ducting from Kingspan Insulation Kingspan releases BIM models for pre-insulated ducting Leading insulated ducting innovators, Kingspan Air Delivery Systems, has become the first pre-insulated ducting manufacturer in Australia to release BIM models for its KoolDuct range of high performance products. The models have been produced in Revit format to the widely-used BIM-MEPAUS (BMA) standard, developed by the Air Conditioning and Mechanical Contractors Association. Kingspan Air Delivery Systems Business Development Manager, Mr. Ross Baynham, says the KoolDuct BIM models will create efficiencies in project delivery. "Projects which use these models can be carried through from design to fabrication almost seamlessly because the duct fabrication machines are able to read directly from the BIM files," he says. "This saves an enormous amount of time and also reduces errors and deviations from the original system design." By engaging multiple disciplines associated with a construction project from engineers, consultants and architects, right through to fabricators, contractors and building product suppliers, projects which employ Building Information Modelling systems and workflows have been demonstrated worldwide to benefit from efficiencies in both time and cost of complete project delivery. Mr. Baynham adds that the KoolDuct system helps achieve regulation compliance in less space than conventional sheet metal ductworked insulated with glasswool blanket. "As a high-performance rigid thermoset insulation, the KoolDuct system can achieve the required R2.0 in only 42 millimetres. This is almost half the thickness of conventional glasswool-insulated systems, which means a lot of precious ceiling space can be saved." "These space savings will be evident when ducted systems are designed using BIM practices." According to Kingspan Air, the KoolDuct system can also reduce air leakage by up to 80% compared to conventional sheet metal systems. The company's Marketing Manager, Mr. Karim Muri, says the system delivers efficiencies on multiple levels. "Energy efficiency is improved with reduced air leakage, installation times are reduced being a lightweight product, and now with BIM models the efficiencies extend to design, fabrication and project delivery," he says. "It truly is most advanced system of air-distribution ductwork available in Australia." The BMA product library now has over 330 manufacturer's Revit families available. Machine molded and cast in ductile iron, the grates and lintel meet Class E 400kN of AS3996.

|

1300 247 235 Malaga, WA, 6090

|

Underfloor Insulation for Suspended

Underfloor Insulation for Suspended Standing Seam System for 3D Geometric

Standing Seam System for 3D Geometric Australian Steel Water Tank by Kingspan

Australian Steel Water Tank by Kingspan Versatile Roofing for Bold Designs by

Versatile Roofing for Bold Designs by Multi-Groove Panels for the Building

Multi-Groove Panels for the Building Dri-Design Flat Rainscreen Facade

Dri-Design Flat Rainscreen Facade Ocean Debris and Waterway Filtration

Ocean Debris and Waterway Filtration Residential Rainwater Harvesting Tanks

Residential Rainwater Harvesting Tanks Zero Carbon Buildings CPD Webinar by

Zero Carbon Buildings CPD Webinar by R-Value Declaration for Insulation

R-Value Declaration for Insulation Flexible Thermo-cellular Reflective

Flexible Thermo-cellular Reflective Updated AS/NZS Standard for R-values

Updated AS/NZS Standard for R-values 6 Star Green Star Rating for

6 Star Green Star Rating for Thermal Bridging & Total R-Values from

Thermal Bridging & Total R-Values from Underfloor Rigid Board Insulation for

Underfloor Rigid Board Insulation for Compliance Deadline for Soffit

Compliance Deadline for Soffit Specify Compliant Building Products with

Specify Compliant Building Products with New Commercial Insulating Soffit Board

New Commercial Insulating Soffit Board Energy Efficient Homes with Insulation

Energy Efficient Homes with Insulation Flexible Insulation for Double Brick

Flexible Insulation for Double Brick