When you're travelling the Seven Seas on-board one of the world's largest cruise ships, there's one thing that instils confidence when it comes to construction - and that is: 'Made in Germany'.

For the construction of the "Serenade of the Seas" - one of four Royal Caribbean International Radiance class passenger ships - the Meyer shipyard in Papenburg, Germany chose a world leader in press-fit pipe technology: Viega.

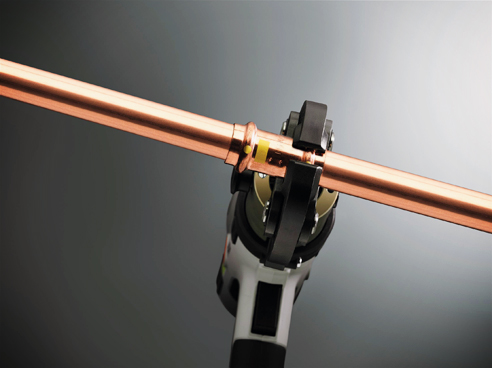

With panoramic vistas and wide-open spaces at every turn, this sleek cruise ship is able to journey to remote waters such as Alaska thanks to things like its low-emission drive technology and the reliable supply of 1.5 million litres of hygienic drinking water per day. And all this water is delivered through the Viega Propress press-fit system that has been used to join over 150 kilometres of on-board piping.

Thanks to Viega, the 2500 passengers and 850 crew are reliably supplied with up to 600 litres of water per person per day via the many bars and restaurants, a sauna, steam room, three swimming pools, three on-deck whirlpools and, of course, every cabin. The water is produced by two evaporators and a reverse osmosis plant, and then distributed through the Propress copper pipe system (the same system that has been approved and readily adopted throughout the Australian plumbing and construction industries for over 10 years). Propress technology was also used throughout the air-conditioning and heating systems on Serenade of the Seas.

Viega also supplies Meyer Werft and other shipbuilders with alternative press-fit products such as the Seapress system. Seapress is specifically designed for the unique and unforgiving challenges that come with shipbuilding. To meet these challenges, including contact with seawater, high corrosion atmospheres and limited personnel to conduct repairs at sea - Viega's Seapress system uses high corrosion-resistant copper-nickel-iron alloy fittings to set the benchmark for quality and long-term reliability at sea.

A primary feature of all of these systems is Viega's cold press connection technology. Brazing, soldering and welding are dangerous in the confined spaces of a ship or a building, and even worse when at sea. In addition, Viega Propress can be installed directly on-site and under the most difficult conditions such as in tight spaces, alongside other assembly sections, and by just one person - without heat, flame or any time-consuming draining of lines.

The time and labour savings delivered by Viega's cold-pressed joint systems was also critical in keeping to the tight deadlines in construction of the Serenade.

Carbon Steel Press Fitting System from

Carbon Steel Press Fitting System from Energy Efficient Press Plumbing

Energy Efficient Press Plumbing Water Pipe System to Eliminate Workplace

Water Pipe System to Eliminate Workplace Copper Press Fitting System of Choice

Copper Press Fitting System of Choice Drinking Water Calculation Software -

Drinking Water Calculation Software - Underground Water Supply Line Fittings

Underground Water Supply Line Fittings Intelligent Drinking Water Systems by

Intelligent Drinking Water Systems by Plumbing & Heating Systems - New Website

Plumbing & Heating Systems - New Website Underground Piping System for Unitywater

Underground Piping System for Unitywater Pressing Tools for Large Construction

Pressing Tools for Large Construction Green Gas & Water Plumbing Systems by

Green Gas & Water Plumbing Systems by Stainless Steel or Copper Press Fittings

Stainless Steel or Copper Press Fittings Propress Fittings for Improved Water

Propress Fittings for Improved Water Potable Water Solutions for Healthcare

Potable Water Solutions for Healthcare Top-Tier Water Safety for Roma Hospital

Top-Tier Water Safety for Roma Hospital Protection of Civil Water Assets with

Protection of Civil Water Assets with Hot & Cold Potable Water for Costco with

Hot & Cold Potable Water for Costco with Press-Fit Systems for Underground

Press-Fit Systems for Underground Copper Press Technology Online Resource

Copper Press Technology Online Resource Ultrafast Pipe Joining Systems from

Ultrafast Pipe Joining Systems from