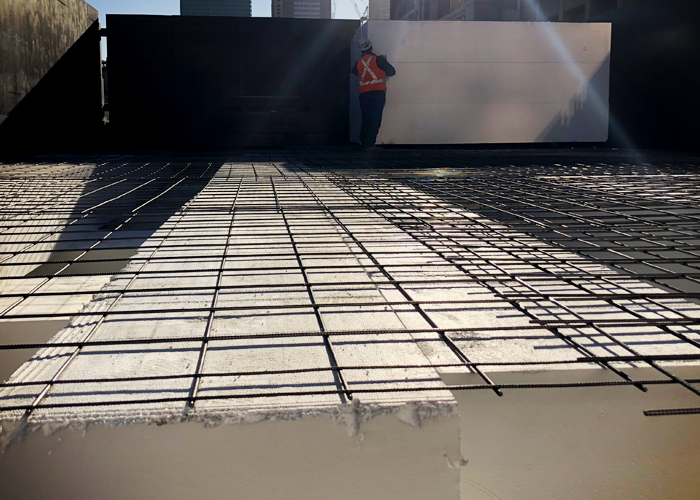

Waffle Pod Slab Design: Construction Process with Foamex Diamond Pods™ Waffle pod slab design is gaining popularity in the construction industry because of its strength, durability, and is perfect for prefabricated or on-site projects. It consists of a flat top surface with a grid-like or waffle pocket system underneath, with joists that are spread out perpendicularly from one another. Built on-ground, a waffle pod slab design eliminates the need for concerted trenching, reducing construction labour time and costs. For minimal impact on the environment builders use Foamex Diamond Pod™, a polystyrene waffle pod void former system that is light yet extremely sturdy and designed to lower the amount of concrete required. Carried by hand, Diamond Pod™ is easier and safer to transport on-site plus is installed without the need for heavy equipment. With its natural air pockets, it also provides a higher level of insulation, with a thermal rating of up to R1.0 (W/MK thermal resistance), meaning, it will help the building achieve a balanced room temperature throughout the year. Foamex Diamond Pod™ Construction Process

For further inquiries, contact Foamex or head over www.foamex.com.au today.

|

03 9720 4200 31-33 Gatwick Road, Bayswater North, VIC, 3153

|

Waffle Pod Void Formers - Diamond Pod by

Waffle Pod Void Formers - Diamond Pod by Polystyrene Foam Blocks for Cool Rooms

Polystyrene Foam Blocks for Cool Rooms Benefits of Recycling Polystyrene Foam

Benefits of Recycling Polystyrene Foam Oversized EPS Foam for Event Props by

Oversized EPS Foam for Event Props by Versatile Polystyrene Sheets Melbourne

Versatile Polystyrene Sheets Melbourne Lightweight Foam Blocks for Sustainable

Lightweight Foam Blocks for Sustainable Polystyrene Underfloor Insulation Sydney

Polystyrene Underfloor Insulation Sydney Robust Polystyrene Blocks for Tunnel

Robust Polystyrene Blocks for Tunnel XPS Slab Edge Insulation for Residential

XPS Slab Edge Insulation for Residential Foam Insulation to Lower Your Carbon

Foam Insulation to Lower Your Carbon Reduce Energy Bills with Rigid

Reduce Energy Bills with Rigid Polystyrene Waste Disposal Guidelines by

Polystyrene Waste Disposal Guidelines by EPS Foam Insulation for Garage Doors

EPS Foam Insulation for Garage Doors Superior Underfloor Insulation for Wood

Superior Underfloor Insulation for Wood XPS Insulation for Energy Efficient

XPS Insulation for Energy Efficient Extruded Polystyrene Foam for

Extruded Polystyrene Foam for Trust Foamex for Polystyrene Foam Block

Trust Foamex for Polystyrene Foam Block Waffle Pod Slabs for Sustainable Homes

Waffle Pod Slabs for Sustainable Homes Polystyrene Foam Packaging for Shipping

Polystyrene Foam Packaging for Shipping Foam Insulation for Draught-free Home by

Foam Insulation for Draught-free Home by